Cr12MoV hot rolled steel round bars

Classification :

PRODUCT DETAILS

Cr12MoV hot rolled steel round bars information

Cr12MoV steel has high hardenability, and those with a cross-section of 300 to 400 mm or less can be completely quenched

It can maintain good hardness and wear resistance at 300 ~ 400℃, its toughness is higher than Cr12 steel, and its volume change is minimal during quenching. It can be used to manufacture various molds and tools with large cross-sections, complex shapes, and withstand large impact loads. For example, punching dies with complex shapes, inserts on complex dies, steel deep drawing dies, wire drawing dies, threaded wire plate, cold extrusion dies, cold cutting scissors, circular saws, standard tools, measuring tools, etc.

Cr12MoV steel is a high-carbon, high-molybdenum lysic steel. Its carbon content is much lower than that of Crl2 steel, and it is added with molybdenum and vanadium elements, which significantly improves the steel's thermal processing properties, impact toughness and carbide distribution . The steel has high wear resistance, hardenability, hardenability, toughness, thermal stability, compressive strength, as well as micro deformation, excellent comprehensive performance and extensive adaptability. The heat softening temperature is 520℃. The cut-off size is below 4mm and can be completely hardened. The wear resistance of this steel is 3~4 times higher than that of a low-strength tool steel, and the quenching volume is small. Hardening depth: oil quenching 200~300mm.

During the crystallization process, a large number of eutectic white carbides are formed (the carbonized substance fraction is about 20%, and the eutectic temperature is about 1150°C). These carbides are very hard and brittle. Although the carbides are broken to a certain degree after billet rolling, the carbides are distributed in bands, slabs, blocks, and piles along the rolling direction, and the degree of segregation increases with the diameter of the steel.

Chemical and Mechanical

Chemical composition% of Cr12MoV steel

| C(%) | Si(%) | Mn(%) | P(%) | S(%) | Cr(%) | Ni(%) | Mo(%) | V(%) | Cu(%) |

|---|---|---|---|---|---|---|---|---|---|

| 1.45~1.70 | ≤0.40 | ≤0.40 | ≤0.030 | ≤0.030 | 11.00~12.50 | ≤0.20 | 0.40~0.60 | 0.15~0.30 | ≤0.30 |

Mechanical properties of grade Cr12MoV

| Proof strength Rp0.2(MPa) |

Tensile strength Rm(MPa) |

Impact energy KV(J) |

Elongation at fracture A(%) |

Reduction in cross sectionon fracture Z(%) |

As-Heat-Treated Condition | Brinell hardness(HBW) |

|---|---|---|---|---|---|---|

| 485(≥) | 154(≥) | 43 | 42 | 44 | Solution and Aging,Annealing,Ausaging,Q+T,etc | 112 |

Cr12MoV equivalents alloy steel

| Steel | Country Code | C(%) | V(%) | Si(%) | Mn(%) | P(%) | S(%) | Cr(%) |

| SKD11 | CNS | 1.4-1.6 | 0.2-0.5 | ≦0.4 | ≦0.6 | ≦0.03 | ≦0.03 | 11.0-13.0 |

| Cr12MoV | GB | 1.45-1.70 | 0.15-0.30 | ≦0.4 | ≦0.4 | ≦0.03 | ≦0.03 | 11.0-12.5 |

| SKD11 | JIS | 1.4-1.6 | 0.2-0.5 | ≦0.4 | ≦0.6 | ≦0.03 | ≦0.03 | 11.0-13.0 |

| X165Cr-MoV12 | DIN | 1.55-1.75 | 0.1-0.5 | 0.25-0.40 | 0.2-0.4 | ≦0.03 | ≦0.03 | 11.0-12.0 |

Cr12MoV steel Range of products

| Product type | Products | Dimension | Processes | Deliver Status |

| Plates/Sheets | Plates/Sheets | 0.08-200mm(T)*W*L | Forging, hot rolling, and cold rolling | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Steel Bar | Round Bar, Flat Bar, Square Bar | Φ8-1200mm*L | Forging, hot rolling and cold rolling, Cast | Black, Rough Turning, Shot Blasting, |

| Coil/Strip | Steel Coil/Steel Strip | 0.03-16.0x1200mm | Cold-Rolled&Hot-Rolled | Annealed, Solution and Aging, Q+T, ACID-WASHED, Shot Blasting |

| Pipes/Tubes | Seamless Pipes/Tubes, Welded Pipes/Tubes | OD:6-219mm x WT:0.5-20.0mm | Hot extrusion, Cold Drawn, Welded | Annealed, Solution and Aging, Q+T, ACID-WASHED |

Heat treatment of Cr12MoV Alloy Steel

spheroidizing annealing:860℃ X 2h furnace cooling to 750℃ and then furnace cooling to 500-550℃, remove out and air cooling

Quenched + tempered:1100℃ X 20min step quenching + 700℃ X 1h tempering,remove out and air cooling

Quenching:1030℃ X 40min oil quenching(800℃ preheating,vacuum 2.5 pa) Tempering: 250℃ X 1h

Application

Cold work dies steel, steel hardenability, quenching, and tempering hardness, wear resistance, strength is higher than Cr12. Used in the manufacture of various cold stamping dies and tools with large cross- sections, complex shapes and heavy working conditions, such as punching die, trimming die, piping dies, deep drawing dies, circular saw, standard tools, and gauges Thread rolling die, etc.

Storage video

Factory appearance and appearance

The company mainly engaged in steel production, sales and other businesses. The main products include all kinds of steel plate, steel pipe, bar, profile and other materials and section steel. At the same time is a number of domestic large steel mill level agents, with a certain price advantage.

Packing and delivery

For many years, the company has been established, adhering to the purpose of "respecting contract, keeping faith, customer first, reputation first, quality first", adhering to the customer demand as the center, to "achieve what customers think, think what customers think" business philosophy, to "one sale, small profit, real price, timely delivery" business principle, we manage all kinds of specifications and materials of steel pipe and profile for customers.

Application field

The main supply fields are: aerospace, national defense equipment, military weapons, chemical industry, shipbuilding, nuclear energy, trains, containers, environmental protection, precision machining, auto parts, machinery, electronic products, molds, medical treatment Equipment, construction, decoration, etc.

Customer Visit Feedback

Over the years since its establishment, the company has been adhering to the purpose of "honoring contract, keeping faith, customer first, reputation first, quality first", adhering to the customer demand as the center, to "reach customer think, think customer think" business philosophy.

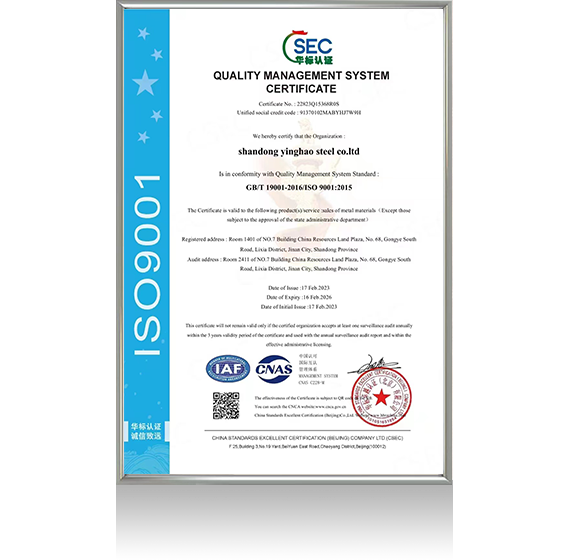

CERTIFICATE OF HONOR

WELCOME TO INQUIRE

The company guarantees the quality of its products with its strong financial strength, advanced management experience and strict quality control system for incoming goods. Excellent products and good reputation are well-known all over the country, and have won the trust and support of major steel mills and customers. Welcome to inquire, negotiate or visit our company in person. Welcome to inquire, negotiate or visit our company in person.

COOPERATIVE PARTNER

FAQ

Q1:Will you offer samples?

A:Yes. We will provide samples according to your needs and send them out within three days after receiving payment.

Q2 : What product information do I need to provide?

A : Please kindly provide the grade, width, thickness, surface treatment requirement should you have and quantities you need to purchase.

Q3 : It's my first time to import steel products, can you help me with it?

A : Sure,we have agent to arrange the shipment, we will do it together with you.

Q4:Do you have the products in stock?

A:We have the products in stock. Also, we can produce for your order.

Q5:Do you offer after-sales services?

A : Of course. We have a perfect after-sales service system, if you have any questions, please feel free to contact us. We will do it to your satisfaction.

Q6:What kind of work does your company do?

A:Our company is a professional manufacturer. We mainly produce stainless steel plate/coil/round rod, carbon steel plate/coil,galvanized plate/coil, PPGI coil, roofing sheet and so on.

Q7:What are the advantages of your company?

A : We have international advanced production equipment, large factory buildings, strong company strength, perfect products and reliable quality.

Q8 : Are you a factory or trading company?

A : We are a professional steel factory with many years of experience, perfect manufacturing process, quality assurance!

RELATED PRODUCTS

GET A FREE QUOTE