410HT Stainless Steel Sheet

Classification :

PRODUCT DETAILS

Product Information

Alloy 410 HT is the basic, general purpose, heat treated version of Type 410. It is a martensitic type, used for general purpose, where corrosion is not severe. Alloy 410 contains a minimum of 11.5% chromium which is just sufficient enough to demonstrate corrosion resistance properties in mild atmospheres, steam, and many mild chemical environments.

Product Details

Chemical Properties:

| C | Mn | Si | P | S | Cr | Ni | |

|---|---|---|---|---|---|---|---|

| 410HT | 0.15 max | 1.00 max | 1.00 max | 0.04 max | 0.03 max | min: 11.5 max: 13.5 |

0.50 max |

Mechanical Properties:

| Grade | Tensile Strength ksi (MPa) min | Yield Strength 0.2% offset ksi (MPa) min | Elongation (% in 50mm) min | Hardness (Brinell) MAX | Hardness (Rockwell B) MAX |

|---|---|---|---|---|---|

| 410HT | 65 (450) | 30 (205) | 20 |

Standards:

- ASTM/ASME: UNS S41000

- EURONORM: FeMi35Cr20Cu4Mo2

- DIN: 2.4660

Corrosion Resistance:

- Good corrosion resistance to atmospheric corrosion, potable water, and to mildly corrosive environments

- Its exposure to everyday activities (sports, food preparation) is generally satisfactory when proper cleaning is performed after exposure to use

- Good corrosion resistance to low concentrations of mild organic and mineral acids

Welding Characteristics

- Readily welded by all standard methods

- To reduce the risk of cracking, it is suggested to pre-heat the work piece to 350 to 400oF (177 to 204oC)

- Post weld annealing is recommended to retain maximum ductility

Heat Treatment

- The proper hot work range is 2000 to 2200oF (1093 to 1204oC)

- Do not work this material below 1650oF (899oC)

Mechanical Properties of Heat Treated 410:

| Heat Treatment | T410 (0.14%C) Hardened 1800°F (982°C) | ||

|---|---|---|---|

| Rockwell Hardness | 0.2% YS, Ksi (MPa) | UTS, Ksi (MPa) | |

| Annealed* | 81 HRB | 45.4 (313) | 80.4 (554) |

| Hardened & Tempered 400°F (204°C) | 43 HRC | 156.1 (1076) | 202.9 (1399) |

| Hardened & Tempered 550°F (288°C) | 40 HRC | 148.3 (1022) | 187.0 (1289) |

| Hardened & Tempered 600°F (316°C) | 40 HRC | 148.8 (1026) | 186.1 (1283) |

| Hardened & Tempered 800°F (427°C) | 41 HRC | 132.9 (916) | 188.5 (1300) |

| Hardened & Tempered 900°F (482°C) | 41 HRC | 122.6 (845) | 154.3 (1063) |

| Hardened & Tempered 1000°F (538°C) | 35 HRC | 127.9 (882) | 154.3 (1063) |

| Hardened & Tempered 1200°F (649°C) | 98 HRB | 85.5 (589) | 111.2 (767) |

Applications:

Applications requiring moderate corrosion resistance and high mechanical properties are ideal for Alloy 410HT. Examples of applications that frequently used Alloy 410HT include:

- Cutlery

- Steam and gas turbine blades

- Kitchen utensils

- Bolts, nuts, screws

- Pump and valve parts and shafts

- Mine ladder rugs

- Dental and surgical instruments

- Nozzles

- Hardened steel balls and seats for oil well pumps

Storage video

Factory appearance and appearance

The company mainly engaged in steel production, sales and other businesses. The main products include all kinds of steel plate, steel pipe, bar, profile and other materials and section steel. At the same time is a number of domestic large steel mill level agents, with a certain price advantage.

Packing and delivery

For many years, the company has been established, adhering to the purpose of "respecting contract, keeping faith, customer first, reputation first, quality first", adhering to the customer demand as the center, to "achieve what customers think, think what customers think" business philosophy, to "one sale, small profit, real price, timely delivery" business principle, we manage all kinds of specifications and materials of steel pipe and profile for customers.

Application field

The main supply fields are: aerospace, national defense equipment, military weapons, chemical industry, shipbuilding, nuclear energy, trains, containers, environmental protection, precision machining, auto parts, machinery, electronic products, molds, medical treatment Equipment, construction, decoration, etc.

Customer Visit Feedback

Over the years since its establishment, the company has been adhering to the purpose of "honoring contract, keeping faith, customer first, reputation first, quality first", adhering to the customer demand as the center, to "reach customer think, think customer think" business philosophy.

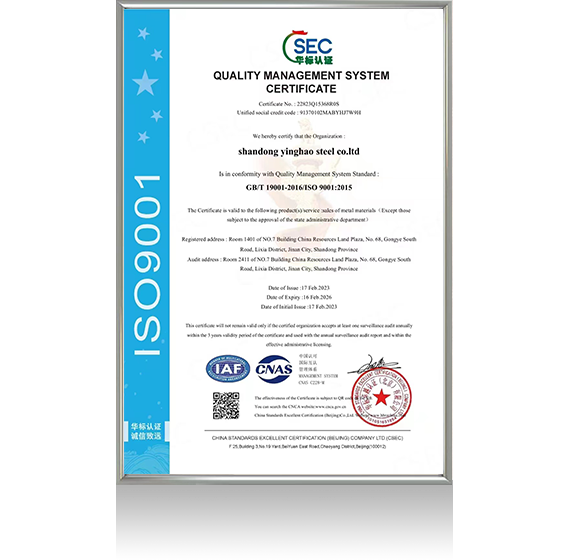

CERTIFICATE OF HONOR

WELCOME TO INQUIRE

The company guarantees the quality of its products with its strong financial strength, advanced management experience and strict quality control system for incoming goods. Excellent products and good reputation are well-known all over the country, and have won the trust and support of major steel mills and customers. Welcome to inquire, negotiate or visit our company in person. Welcome to inquire, negotiate or visit our company in person.

COOPERATIVE PARTNER

FAQ

Q1:Will you offer samples?

A:Yes. We will provide samples according to your needs and send them out within three days after receiving payment.

Q2 : What product information do I need to provide?

A : Please kindly provide the grade, width, thickness, surface treatment requirement should you have and quantities you need to purchase.

Q3 : It's my first time to import steel products, can you help me with it?

A : Sure,we have agent to arrange the shipment, we will do it together with you.

Q4:Do you have the products in stock?

A:We have the products in stock. Also, we can produce for your order.

Q5:Do you offer after-sales services?

A : Of course. We have a perfect after-sales service system, if you have any questions, please feel free to contact us. We will do it to your satisfaction.

Q6:What kind of work does your company do?

A:Our company is a professional manufacturer. We mainly produce stainless steel plate/coil/round rod, carbon steel plate/coil,galvanized plate/coil, PPGI coil, roofing sheet and so on.

Q7:What are the advantages of your company?

A : We have international advanced production equipment, large factory buildings, strong company strength, perfect products and reliable quality.

Q8 : Are you a factory or trading company?

A : We are a professional steel factory with many years of experience, perfect manufacturing process, quality assurance!

RELATED PRODUCTS

GET A FREE QUOTE